Earlier this year, Fine Linen and Bath welcomed Celso de Lemos bedding -- an eponymous new collection from the founder of Abyss Habidecor -- to our family of luxury linen brands. At the time, we had hoped to interview Mr. de Lemos; however, he prefers to maintain a low profile to keep the focus on his products and craftspeople. Instead, the Fine Linen and Bath Brand Manager, Erika Cellupica, paid a visit to Mr. de Lemos in his native Portugal, where she visited his vineyard, hotel, and factories. Below, she relates her impressions and insights into this textile visionary.

Dearest Fine Linen and Bath Clients,

I’m writing to share one of the singular experiences of my decade-long career at Fine Linen and Bath, one that I’m certain will interest you.

Last month, I had the privilege of visiting Celso de Lemos at Quinta de Lemos, his vineyard in Silgueiros, Portugal (a stunning village in the Viseu region about an hour and a half from Porto). Nestled between two mountain ranges, this breathtaking property is home not only to a vineyard, but also a guest house, for visitors to the vineyard and factories, a Michelin-starred restaurant, and a growing olive oil production operation. Viseu is also the location of the Habidecor and Celso de Lemos factories, with the Abyss towel factory about a half-hour drive away in a town called Tondela.

Photo of Quinta de Lemos vineyard and property

If I could describe Celso de Lemos in a sentence, it would be this: He is the most generous, gracious, and friendly company owner I have ever met. With his growing empire to run, we had expected to meet him for five minutes or so but were overwhelmed by the attention he gave us. He ate every meal with us, accompanied us on every factory tour, and even prepared a memorable dinner of local fish, spinach, and rice for us on our first evening there. He welcomed us, saying, “You are my customers, but more importantly, you are my friends.” By the end of our brief trip, we felt exactly the same.

Photo of Erika Cellupica and Tom Ceconi with Celso de Lemos the founder of Abyss Habidecor

As a textile innovator who built the Abyss Habidecor company from the ground up, Celso is a true Renaissance man whose talents and interests make him a fascinating host. But with all the breadth of his knowledge and passions, he manages to focus on each singular detail of his textiles, from finest raw materials to yarn to finished products. We took a tour of the Habidecor rug factory, where Celso taught us about cotton and shepherded us through the production cycle of a reversible rug. Here’s a bit of what we learned.

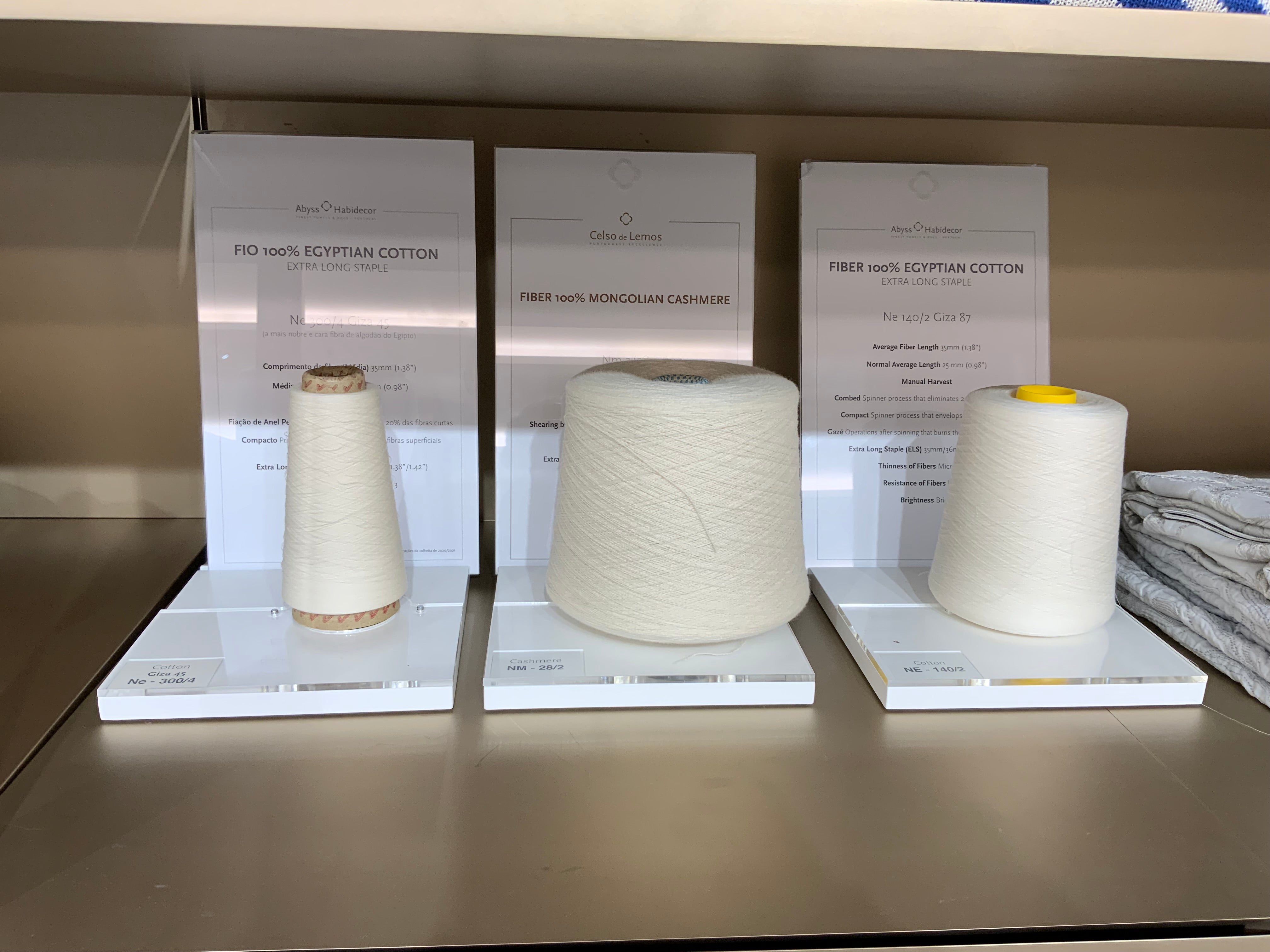

Giza Cotton: Celso taught us a Giza cotton master class, where we learned more about this rare and special cotton. Consider this: 27 million tons of cotton are produced globally every year. Of that, 500,000 tons are Egyptian cotton, with Giza Extra-long-staple cotton accounting for just 4,000 tons of cotton a year. It is that rare. globally. 500k tons is Egyptian. 4000 tons a year is Egyptian Giza cotton extra-long-staple (ELS). Celso carefully unraveled a “staple” of extra long staple cotton that was about two inches long to show us what it looks like. Several times a year, the company randomly selects bobbins of yarn and sends them to an independent quality tester to ensure that they are getting only 100 percent ELS cotton (used for sheets and towels) or LS Giza cotton (used for rugs).

Rug Production: Any rug that is tufted -- Habidecor Must and Reversible rugs or the Abyss Double bath mat -- is threaded by hand through a sewing machine. In contrast, fashion rugs are made on a large weaving machine that creates the pattern on a bigger scale with custom shapes and sizes available. The non-slip backing is also attached by machine (not spray) and is genuine, natural latex (not synthetic).

Photo of a rug tuffting as well as the non-slip machine

Celso with his first tuffting machine

The Dyeing Process: I found this particularly interesting. Abyss and Habidecor are known for their dazzling range of beautiful color options, which means that dye lots must be precisely matched. To ensure color choice consistency, the single-color rugs are piece-dyed after production. If a rug has multiple colors, the yarn spools are dyed. Most fascinating of all: to ensure perfect color consistency, the factory employs a chemist who tests the pH of the water, which can grow more acidic when it rains. Testing the pH before dyeing allows the factory to make any necessary adjustments to the dye formula to ensure a perfect color match.

Made to order means exactly that: When you are browsing our site looking at rugs, the cotton you will receive is at that moment likely undyed and in the factory, waiting for your direction to be fashioned into the precise size and color rug you want. Every rug is custom-made to order, transformed from yarn to finished rug in your home in four to five weeks.

Habidecor Rugs Being made

So while I may not have officially interviewed Celso, I can certainly say that spending this time with him and witnessing his care, passion, and attention to even the smallest detail, tell me so much about who he is. I left Portugal feeling enriched by his friendship, and prouder than ever to represent Abyss, Habidecor, and Celso de Lemos linen.

Celso’s Mom and her sewing machine

Watch this space for more Letters from Portugal, where we discuss Abyss towels and Celso de Lemos bedding.

Kind regards,

Erika