This article is the second in a series from Fine Linen and Bath Brand Manager, Erika Cellupica, who recently paid a visit to the factories in Portugal where Abyss Habidecor bath linen and Celseo de Lemos bedding are made. Here she shares her impressions and insights about what she saw, including a glimpse into the precision craftsmanship that goes into making Abyss towels.

Dearest Fine Linen and Bath Clients,

Earlier this year, I paid a visit to the vineyard and factories of Celso de Lemos, founder of the legendary Portuguese linen brand, Abyss Habidecor. This was truly one of the highlights of my decade-long career at Fine Linen and Bath. I was treated as an honored guest at Celso's hotel vineyard, which is nestled between two mountain ranges in the Viseu region and features a Michelin-starred restaurant. I also had the privilege of visiting the factories where Celso de Lemos and Abyss Habidecor home linen are made.

In my earlier blog, I wrote about Celso de Lemos and his passion for detail; you can read about that here. Today, I'm sharing my impressions from a visit to the Abyss towel factory, which is about a half-hour drive away in a town called Tondela. Our guide for the tour was Nuno, who took us step-by-step through the process of turning cotton thread into a finished towel.

Keeping the Staple: The Foundation of a Luxurious Bath Towel

Our first stop on the tour was the room where the pallets of extra-long-staple cotton fibers are stored on bobbins. As you may know, the term "staple" refers to the length of cotton fiber; the longer the staple, the stronger, softer, and more durable the cotton. Longer staple cotton also has unparalleled absorbency, which is essential for bath towels and bath mats. The goal for weaving cotton fiber into luxurious towels is to "keep the staple," that is, to protect the integrity of this fine fiber and the extra softness. While other companies may outsource this process, Abyss weaves their own cotton thread by setting dozens of the bobbins up on a machine that pulls them together into a large bolt of thread. To minimize waste, there is a special formula used to calculate exactly how much thread is needed.

Transforming Yarn into Fabric

We next ventured into the weaving room, where the terry base fabrics for the towels are made. If the towel has a design on it, the machines have special wires that pull the threads to create the specific pattern. Once the bolts of fabric are woven, the fabric is carried to a shelf where it sits until it's time to be cut and sewn into the various products.

Cutting and Sewing: Traditional Craftsmanship Meets Innovation

When the fabric is ready to be cut, it is carried into yet another room where workers place the fabric onto machines programmed with digitized templates. This allows every piece of fabric to yield the most pieces with the goal of zero waste. Once cut, the fabric moves to a dedicated sewing station where teams sew the pieces, one sitting and one standing on an anti-fatigue mat. These teams switch sides every two hours to prevent repetitive motion strain. Being fully trained on how to sew Abyss towels is a process that takes around five years.

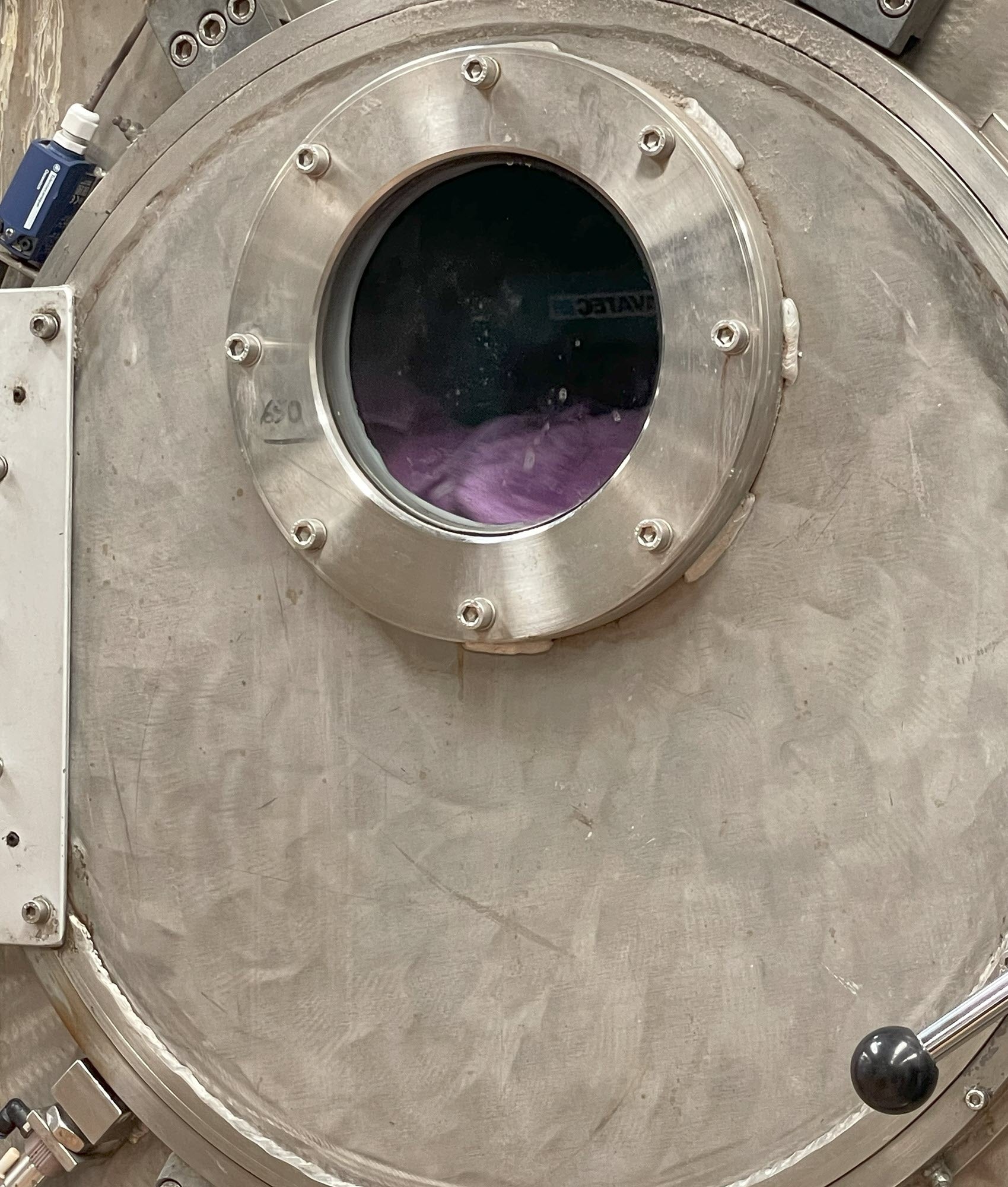

The Dyeing Room: The Magic of Color

If you love Abyss towels as much as we do, you likely know that one of their standout features is the range of rich colors available. Abyss towels are piece-dyed in large vats after the label and border are attached to ensure color consistency. This process takes about eight hours in the machine where the towels are not only dyed but also treated to prevent shrinkage and increase absorbency and durability, finishing with a wash cycle.

Embroidery: A Finishing Touch

Our last stop was the embroidery room, where skilled textile workers embellish any towels that feature embroidery. Their work is true artistry!

I hope I've been able to give you some idea of the artistry and technological mastery that goes into every Abyss towel. It was truly something to behold; the experience has given me a renewed appreciation for the quality and generations of care that goes into crafting these fine linens.

To learn more, visit the Abyss & Habidecor collection page at Fine Linen and Bath. Also, feel free to contact me or one of our design consultants with any questions you might have. It would be our privilege to help you choose your perfect Abyss towels.

Note: If you are new to Abyss towels, we recommend you begin by considering Abyss Super Pile Towels, the most popular style of Abyss Towel. Heavy and absorbent at a plush 700 GSM weight, the Super Pile Towel collection features multiple sizes, including a Super Pile bath towel, fingertip towel, hand towel (guest towel) in three sizes, bath sheet in two sizes, bath mat in two sizes; and washcloth. The Abyss Super Pile towel collection also comes in the widest range of color options (60 stunning shades) and pairs with a coordinating bath rug collection from Habidecor. Truly, you cannot go wrong with Abyss Super Pile.

Kind regards,

Erika Cellupica